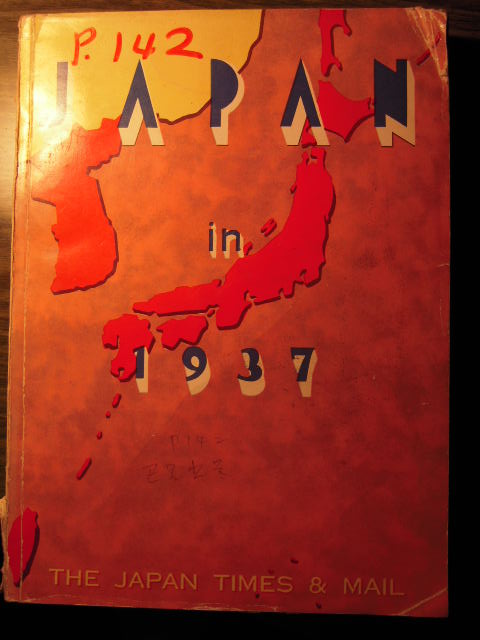

THE JAPAN TIMES & MAIL - JAPAN IN 1937 [箱木一郎 曲面印刷 ichiro hakogi]

JAPAN IN 1937 – THE JAPAN TIMES & MAIL

『一九三七年の日本』 昭和十二年六月五日発行 定価金七円

編集兼発行者 東京市麹町区内幸町一丁目六番地 株式会社 ジャパン・タイムス社

発行所 株式会社 ジャパン・タイムス社

TO PARIS EXPOSITION

The “Kurba Gravo” Japan-Made Invention Used For Decalcomania Printing

Of the various exhibits representing the old and new cultural aspects of Japan which will be displayed in the “Japan Hall” of the International Exposition opening in Paris on May 1, the section dealing with the newest and most practical Japanese inventions, to be shown in the Scientific Room of the Hall, is bound to arouse the greatest interest.

44 Inventions

Forty-four of Japan’s leading inventions, carefully selected by Dr. Jiro Tsuji, a member of the Institute of Physical and Chemical Research of Japan, with the aid of prominent specialists, is being placed upon exhibition for the world to inspect and admire. One of them is the “Printing Press for Curved Surfaces,” not only used in the ceramic and glass making industries, but also applicable to all articles which have 3 dimension for printing designs on finished products, and invention of Mr. Ichiro Hakogi, holder of several international patents, and a graduate of the Kansei Gakuin.

The Hakogi’s Kurba Gravo is an epoch-making invention, and it is the only curved-surface printing machine now in use.

Work Rewarded

Work Rewarded

For many years, despite the remarkable progress made in the direct printing field, it was believed impossible to create a machine for printing on a curved surface, such as for work on bottles and ceramic ware.

As early as 1750, John Sadler, an English printer, invented decalcomania process on July

27, 1756, with the aid of his helper, Gay Green.

With his invention he was able to print patterns on 1,200 articles every six hours, doing the work of at least 100 men.

But revolutionary as his invention was it cannot be said to be direct printing on a curved surface for it had to undergo the process of transcription. Since then many attempts by both American and European journeymen have been made to find a suitable method but none have succeeded.

It was not until January 18, 1932 that Mr. Hakogi, after years of experimentation, came upon his new discovery. He worked on the air suction process. He had found that other experimenters failed to make perfect designs because between the diaphrane and the product to be printed a thin layer of air existed making it impossible to have perfect contact. By the use of sucking apparatus, a vacuum would be created, assuring a perfect design.

Hakogi, Inventor

With the use of the Hakogi Kurba Gravo press he can print ceramic work and glassware in six colors employing all kinds of patterns. The construction of the press is so that any article, no matter what shape, can be mechanically printed and designed.

However, in view of the high cost of manufacturing the new machine, the Government desirous of producing a practicable printing press which could be marketed at a reasonably low price gave to Mr. Hakogi a \9,000 grant as encouragement for further research. With the aid of Mr. Yoshitaka Seki, an engineer using the same principle, the pair a year later completed a printing press which could print on bottles.

Wins Prize

In 1934 the inventor was honored with an Imperial Prize for the invention. The new machine operates so smoothly that it prevents ceramic and glass from cracking and prints a clear design on the article. Mr. Hakogi is expected to have left for Paris late March where he will introduce the new machine to the world-at-large.

The Japan Kurba Gravo Laboratories are located at Akatsuka Nagoya, Japan. Correspondence can be addressed to P.O. Box 55, in care of the company.

(The Japan Times & MaillのJAPAN in 1937 p142より全文)

『一九三七年の日本』 昭和十二年六月五日発行 定価金七円

編集兼発行者 東京市麹町区内幸町一丁目六番地 株式会社 ジャパン・タイムス社

発行所 株式会社 ジャパン・タイムス社

TO PARIS EXPOSITION

The “Kurba Gravo” Japan-Made Invention Used For Decalcomania Printing

Of the various exhibits representing the old and new cultural aspects of Japan which will be displayed in the “Japan Hall” of the International Exposition opening in Paris on May 1, the section dealing with the newest and most practical Japanese inventions, to be shown in the Scientific Room of the Hall, is bound to arouse the greatest interest.

44 Inventions

Forty-four of Japan’s leading inventions, carefully selected by Dr. Jiro Tsuji, a member of the Institute of Physical and Chemical Research of Japan, with the aid of prominent specialists, is being placed upon exhibition for the world to inspect and admire. One of them is the “Printing Press for Curved Surfaces,” not only used in the ceramic and glass making industries, but also applicable to all articles which have 3 dimension for printing designs on finished products, and invention of Mr. Ichiro Hakogi, holder of several international patents, and a graduate of the Kansei Gakuin.

The Hakogi’s Kurba Gravo is an epoch-making invention, and it is the only curved-surface printing machine now in use.

For many years, despite the remarkable progress made in the direct printing field, it was believed impossible to create a machine for printing on a curved surface, such as for work on bottles and ceramic ware.

As early as 1750, John Sadler, an English printer, invented decalcomania process on July

27, 1756, with the aid of his helper, Gay Green.

With his invention he was able to print patterns on 1,200 articles every six hours, doing the work of at least 100 men.

But revolutionary as his invention was it cannot be said to be direct printing on a curved surface for it had to undergo the process of transcription. Since then many attempts by both American and European journeymen have been made to find a suitable method but none have succeeded.

It was not until January 18, 1932 that Mr. Hakogi, after years of experimentation, came upon his new discovery. He worked on the air suction process. He had found that other experimenters failed to make perfect designs because between the diaphrane and the product to be printed a thin layer of air existed making it impossible to have perfect contact. By the use of sucking apparatus, a vacuum would be created, assuring a perfect design.

Hakogi, Inventor

With the use of the Hakogi Kurba Gravo press he can print ceramic work and glassware in six colors employing all kinds of patterns. The construction of the press is so that any article, no matter what shape, can be mechanically printed and designed.

However, in view of the high cost of manufacturing the new machine, the Government desirous of producing a practicable printing press which could be marketed at a reasonably low price gave to Mr. Hakogi a \9,000 grant as encouragement for further research. With the aid of Mr. Yoshitaka Seki, an engineer using the same principle, the pair a year later completed a printing press which could print on bottles.

Wins Prize

In 1934 the inventor was honored with an Imperial Prize for the invention. The new machine operates so smoothly that it prevents ceramic and glass from cracking and prints a clear design on the article. Mr. Hakogi is expected to have left for Paris late March where he will introduce the new machine to the world-at-large.

The Japan Kurba Gravo Laboratories are located at Akatsuka Nagoya, Japan. Correspondence can be addressed to P.O. Box 55, in care of the company.

(The Japan Times & MaillのJAPAN in 1937 p142より全文)

2010-01-31 15:18

nice!(0)

コメント(0)

トラックバック(0)

コメント 0